What Is Parallel Flow Heat Exchanger

What is parallel flow heat exchanger

A counter-flow heat exchanger is one in which the direction of the flow of one of the working fluids is opposite to the direction to the flow of the other fluid. In a parallel flow exchanger, both fluids in the heat exchanger flow in the same direction.

What is a parallel flow?

A parallel flow pattern, also referred to as a cocurrent flow, is one in which the shellside and tubeside fluids flow in the same direction. This is widely seen in double-pipe heat exchangers and can be replicated in shell and tube heat exchangers as well, according to Bright Hub Engineering.

Which is better parallel or counter flow heat exchanger?

Counter flow heat exchangers are inherently more efficient than parallel flow heat exchangers because they create a more uniform temperature difference between the fluids, over the entire length of the fluid path.

What is parallel flow or co current direction?

The co-current (or parallel) flow is characterized by the two fluid streams entering together at one end of the HX, flowing through in the same direction (i.e., parallel to each other), and leaving together at the opposite end of the HX.

What is the difference between parallel flow and counter flow?

With parallel flow the fluids are travelling through the heat exchanger in the same direction where as a counter flow installation will have the fluids flowing against each other in opposite directions.

Where does parallel flow heat exchanger used?

They are widely used in both heating and cooling applications. An everyday example of a heat exchanger is the combustion engine of a car, where cooling fluid passes through inside the coils of a radiator as outside air moves around the radiator.

Why do we use parallel flow?

However, there are applications where parallel flow has its benefits, such as when limiting the transfer of heat is recommended. Another advantage if parallel flow heat exchangers are used is that outlet temperature of the fluid being cooled can reach a limiting temperature.

What are the advantages of a parallel flow system?

Parallel flow is similar to a electrical parallel circuit in which several parallel flow circuits of equal length connect to a supply header and a return header. A benefit of parallel is that a small diameter pipe can be used due to lower pressure drops and same money on installation.

Why is parallel flow less efficient?

The key difference between counterflow and parallel flow heat exchanger is that counterflow heat exchanger is highly efficient because it can exchange a maximum amount of heat, whereas parallel flow heat exchanger is less efficient because it cannot exchange a high amount of temperature.

What are the 3 types of heat exchangers?

What Are The Different Types Of Heat Exchanger?

- Finned Tube Heat Exchanger Or Air Cooled Heat Exchanger. Suitable for: air/gas to fluid.

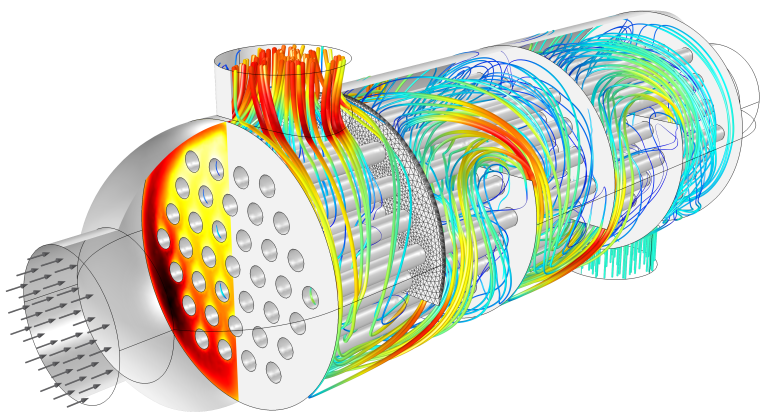

- Shell And Tube Heat Exchanger. Suitable for: fluid to fluid / fluid to gas. ...

- Plate Heat Exchanger Or Gasket Plate Heat Exchanger. Suitable for: fluid to fluid / fluid to vapour.

Which flow is better for heat exchanger?

At Reynolds numbers above 10,000 there is substantial breaking away from the tube wall and the condition is described as turbulent flow with significant mixing of the boundary layer and the bulk fluid. This is the most efficient area for heat exchangers to work in.

What are the 4 types of heat exchanger?

4 Types of Heat Exchangers and Applications

- Double Tube Heat Exchangers: Double tube heat exchangers use what is known as a tube within a tube structure.

- Shell and Tube Heat Exchangers: ...

- Tube in Tube Heat Exchangers: ...

- Plate Heat Exchangers:

What is fouling in heat exchanger?

Fouling is generally defined as the deposition and accumulation of unwanted materials such as scale, algae, suspended solids and insoluble salts on the internal or external surfaces of processing equipment including boilers and heat exchangers (Fig 1).

Does flow direction matter in a heat exchanger?

Opposing directions. To attain maximum heat transfer from a heat exchanger, it's important that the fluids exchanging heat flow in opposite directions. This is called “counterflow” heat exchange. It produces the highest log mean temperature difference (LMTD) between the two fluids.

What is fouling factor in heat exchanger?

The fouling factor represents the theoretical resistance to heat flow due to a build-up of a layer of dirt or other fouling substance on the tube surfaces of the heat exchanger, but they are often overstated by the end user in an attempt to minimise the frequency of cleaning.

Which heat exchanger is most efficient?

Plate exchanger is the most efficient due to turbulent flow on both sides. High heat-transfer coefficient and high turbulence due to even flow distribution are important. However, a plate heat exchanger regenerator is restricted to low viscosities.

What is the difference between cross flow and counter flow heat exchanger?

The counterflow heat exchanger has two zones where heat transfer occurs. A crossflow zone (triangular parts) where air flows identically as it does in a crossflow heat exchanger, and a counterflow zone (rectangular parts) with genuine counterflow.

Which is better cross flow or counter flow?

Crossflow towers will serve better for maintenance access, variable flow, and cold weather operation. Counterflow towers may serve better in tight spaces under 750 tons, or in spaces where lower operating weight is required.

What is the maximum efficiency for parallel flow heat?

What is the maximum efficiency for parallel flow heat exchanger? Explanation: No matter how large the exchanger be or how high be the flow of overflow at transfer coefficient, the maximum efficiency for parallel flow heat exchanger is 5%.

What is the application of heat exchanger?

Heat exchangers are used to transfer heat from one medium to another. These media may be a gas, liquid, or a combination of both. The media may be separated by a solid wall to prevent mixing or may be in direct contact.

Post a Comment for "What Is Parallel Flow Heat Exchanger"